Automated Plastic Processing Solutions

As a 10+ years professional plastic auxiliary machinery manufacturer, Kaifeng can help you with the planning and deployment of the entire plant.

Plastic raw material storage, drying, transportation mold temperature control, molding cooling system waste crushing and recycling system equipment

Featured Machines

Heat and Cold Exchange Equipment

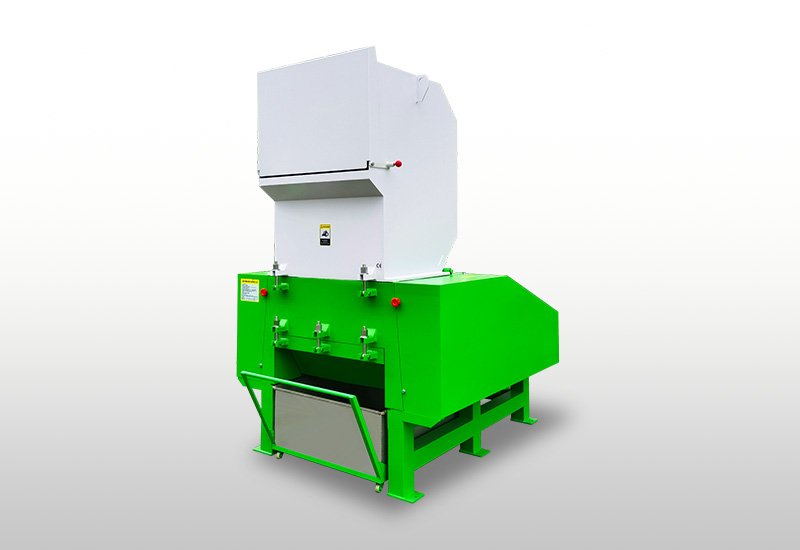

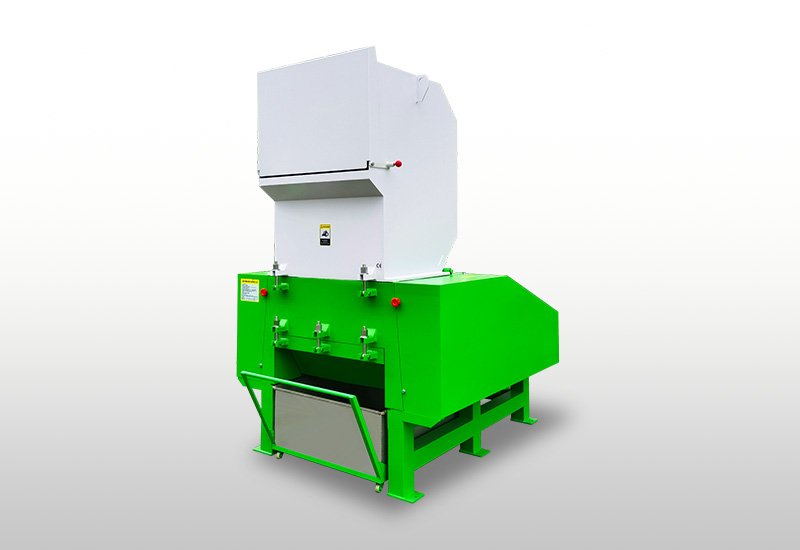

Crushing and Recycling Equipment

Mixing and Dosing Equipment

The equipment utilizes advanced control systems, electrical components and high-quality stainless steel materials to ensure mixing uniformity and metering precision while ensuring that the raw materials are not contaminated. It is suitable for mixing all kinds of plastic raw materials and color masterbatches to meet the needs of different production processes.

Dehumidifying and Drying Equipment

Feeding and Conveying Equipment

About KAIFENG Machinery

Kaifeng is a professional manufacturer that integrates the research and development, manufacturing and sales of plastic peripheral machinery. Its equipments are exported to more than 20 countries and regions such as Europe, America, Africa and Southeast Asia.

Kaifeng’s factory building covers an area of 20,000 square meters. It has an enterprise research and development room and a technology center, and also owns modern production lines with advanced processes and mature technologies.

Market Abroad

Products are exported to more than 20 countries and regions.

Technical Center

It has an enterprise research and development room and a technology center.

Certificate

The company fully implements the ISO9001 international quality system.

Management Team

An outstanding international operation and management team.

Contact us to provide you with services

Kaifeng Machinery, specializing in plastic machine including plastic granulator, industrial water chiller, hopper loader, plastic dryer, and plastic mixer and so on, fully implements the ISO9001 international quality system and relies on advanced production experiment and testing equipment as well as an outstanding international operation and management team.

Strong Durability

Adopting high hardness alloy knives, double-layer soundproof structure, with copper core motor, the life span is extended by 50%, which reduces the cost of equipment replacement.

High Quality Standards

The use of high quality materials such as copper core motors reflects Kaifeng's commitment to producing reliable and durable machinery.

Competitive Pricing and Flexibility

Attractive pricing and customization options that are 10%-15% lower compared to similar products, along with flexible payment options and long-term warranties.

Global Customer Validation

Products are exported to more than 20 countries, serving over 500 companies with an 85% customer reorder rate.

Get more infomation about PLASTIC machinery

Learn more about the plastic machine industry and related KaiFeng activities to boost your plastic machinery business.

The 13th China International Beverage Industry Technology...

KAIFENG Plastic Machinery is a professional manufacturing, manufacturing, sales and service as one of the plastic auxiliary equipment and industrial temperature control...

Analysis and Solutions to Common Problems of Plastic Mixers by ...

Plastic mixers may encounter some common problems during daily use. Anhui Kaifeng Plastic Machinery Co., Ltd., with years of industry experience, will analyze the causes of these problems and...

CBST 2025 Shanghai: Kaifeng Machinery’s One-Stop Automation Solutions...

March 5-7, 2025, the 13th China International Beverage Industry Science & Technology Exhibition (CBST·2025) will grandly open at Hall N1-N3, Shanghai New International Expo Centre...