Introduction to 400 Type Hopper Loader

The 400 Type Hopper Loader is high-tech automation equipment destined for the plastics processing industry. It finds extensive application in injection molding, the production of extrusion, blow molding, and other fields. The primary function of this equipment is to automatically vacuum plastic raw materials from storage containers or conveyors and then transport them to the processing equipment’s hopper so that the raw materials can be fed in automatically. It is through smart operations and design that it enhances production efficiency really, reducing the otherwise high labor costs and intensity and is thus the right solution in the plastics processing industry.

Features of 400 Type Hopper Loader

1.Intelligent Function

Fully auto PC operation programmed: There is an intelligent control system equipped on the unit, easy to operate, and easy to maintain. Users can just refer to the interface to set parameters very easily.

Motor protection device: With the built-in function of motor protection, it will shut down automatically when there is an overload or an abnormal condition detected, which protects the equipment from any damage.

Lack of material alarm function: The equipment shall not have any ability to sound an alarm when the raw material is insufficient. In time, the user will be aware when to replenish raw material in order to ensure production continuity.

2.High-quality materials

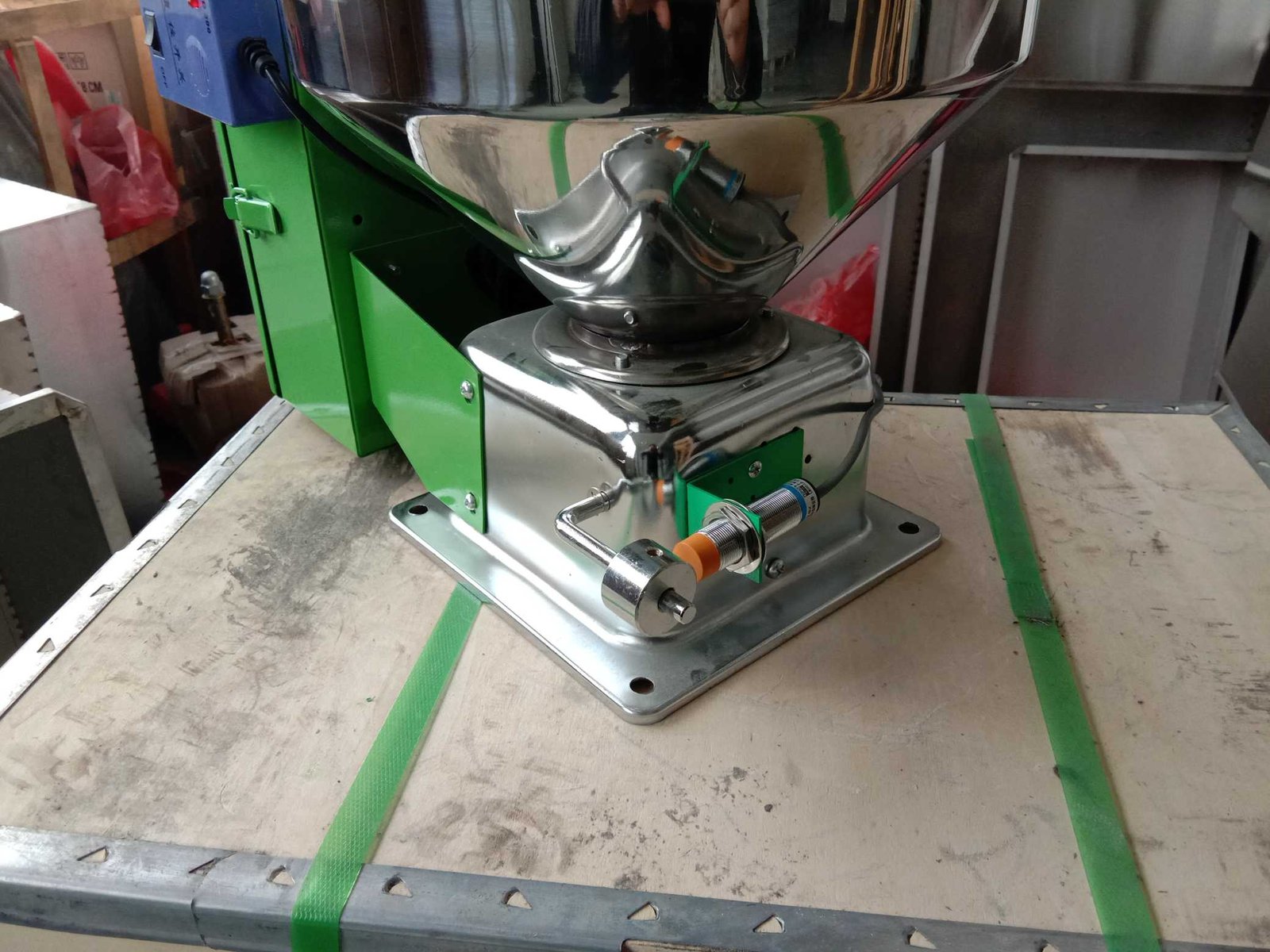

Stainless steel hopper: The hopper shall be made from high-quality stainless steel, therefore, there shall be no rust, and shall therefore be easy to maintain cleanliness to ensure raw material purity plus equipment durability.

Independent filtering device: high-efficiency filtering system, conveniently remove dust accumulation, keep the inside of the equipment clean, and extend the service life.

3. Safety design

Mainframe and barrel separation design: The equipment adopts a modular design, the mainframe and the barrel are separated, the operation is safe and easy, and it is easy to maintain and clean.

Photoelectric eye detector (optional): Some models can be equipped with a photoelectric eye detector, which is directly installed at the entrance of the equipment to monitor the supply status of raw materials in real time.

Parámetros técnicos

| Modelo | X400G | |||

|---|---|---|---|---|

| Motor | Type | Induction | ||

| Power | Kw | 0.75 | ||

| Conveying Capacity | Kg/h | 330 | ||

| Lift | m | 4 | ||

| Capacidad | L | 12 | ||

| Pipe Diameter | mm | \ \ \ \ \ Ф38 | ||

| Dimensiones | L(mm) | 450 | ||

| W(mm) | 370 | |||

| H(mm) | 660 | |||

| Weight | Kg | 27 | ||

Advantages of 400 Type Hopper Loader

1. Reduce production costs

Automatic feeding: Reduce the need for manual handling of raw materials and significantly reduce labor costs.

Alta eficiencia y ahorro de energía: The equipment has low power consumption, effectively reduces energy consumption, and saves operating costs for enterprises.

2. Mejorar la eficacia de la producción

Continuous feeding: Ensure uninterrupted supply of raw materials, avoid production interruptions, and improve overall production efficiency.

Quick material change: The modular design makes the material change process faster and reduces downtime.

3. Avoid production risks

Overload protection: The equipment has a built-in protection mechanism to avoid equipment damage and production accidents caused by overload.

Dust control: Independent filtering device effectively reduces dust pollution, improves the working environment, and meets environmental protection requirements.

Datos

Escenarios de aplicación

400 Type Hopper Loader is suitable for the following industries:

Plastic processing industry: used for automatic feeding of injection molding machines, extruders and other equipment.

Plastic modification industry: realize accurate proportioning and continuous supply of multiple raw materials.

Plastic recycling industry: efficiently process recycled plastic particles and improve recycling efficiency.

PREGUNTAS FRECUENTES

1. Does 400 Type Hopper Loader support customization?

A: Yes, we can customize parameters such as hopper capacity and power according to customer needs.

2. ¿Con qué frecuencia hay que realizar el mantenimiento del equipo?

A: It is recommended to perform comprehensive maintenance once a quarter. Daily maintenance only requires cleaning the filter device and checking the motor status.

3. Is 400 Type Hopper Loader suitable for high temperature environments?

A: The equipment uses high temperature resistant materials and can operate normally in an environment not exceeding 250℃.