Introduction to Water-cooled screw chiller

Water-cooled screw chiller is a high-efficiency cooling equipment designed for industrial and commercial fields. As one of the core equipment of industrial cooling system, it is widely used in plastic processing, chemical, pharmaceutical, food and beverage, injection molding, die casting, rubber molding, composite molding and other industries with its excellent energy efficiency and stable operation performance. Whether it is to provide precise temperature control for production equipment or to create a comfortable indoor environment for commercial places, this chiller can meet diverse needs.

Features of Water-cooled screw chiller

1. High efficiency and energy saving, reducing operating costs

The water-cooled screw chiller adopts advanced screw compression technology and is equipped with a graded energy control system, which can automatically adjust the operating status according to the actual load demand. Its compression ratio can be as high as 20, and its energy efficiency ratio (EER) value is significantly higher than similar products on the market. When operating at partial load, the equipment can still maintain high efficiency and save electricity significantly.

2. Stable and reliable, extending equipment life

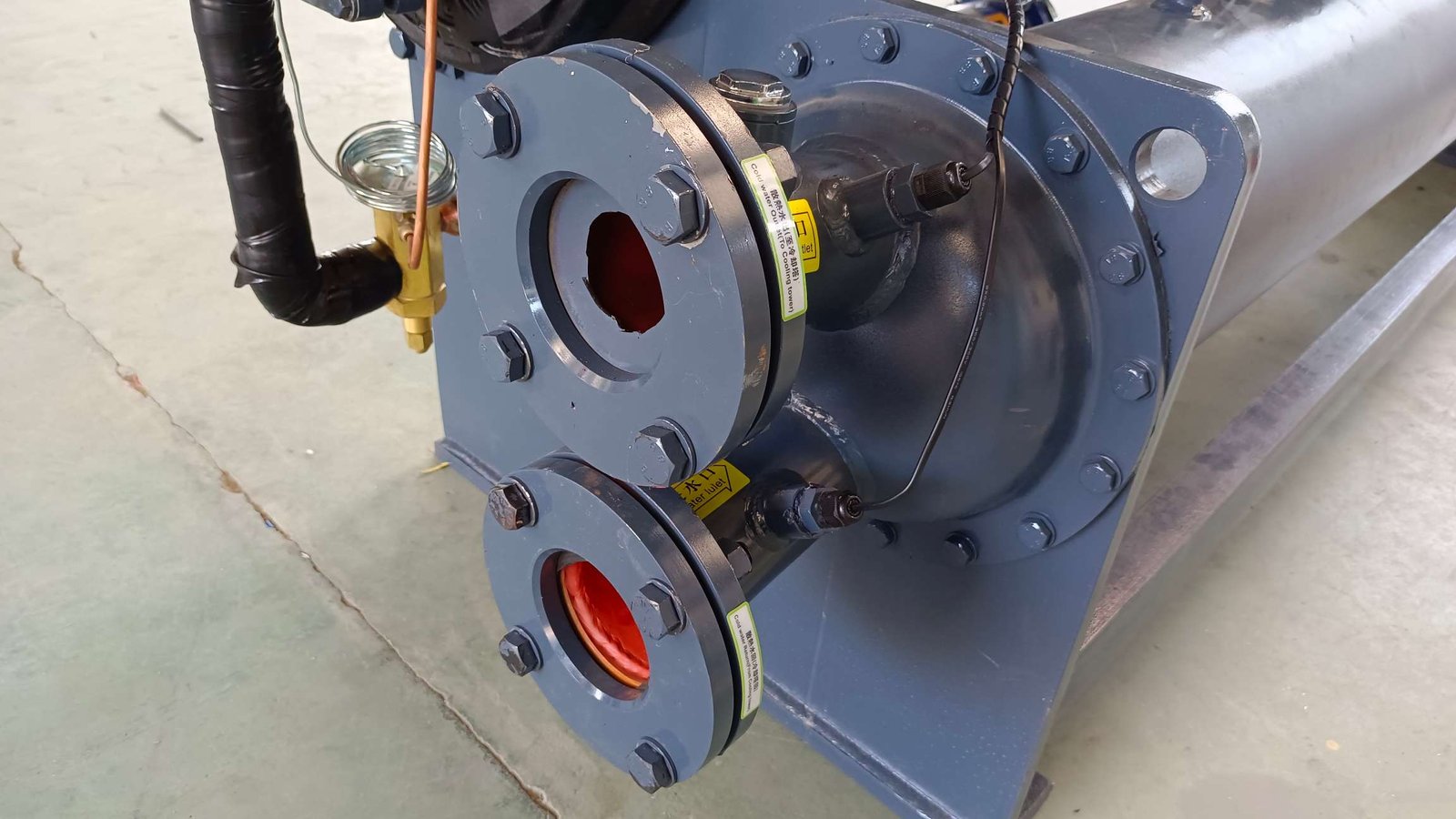

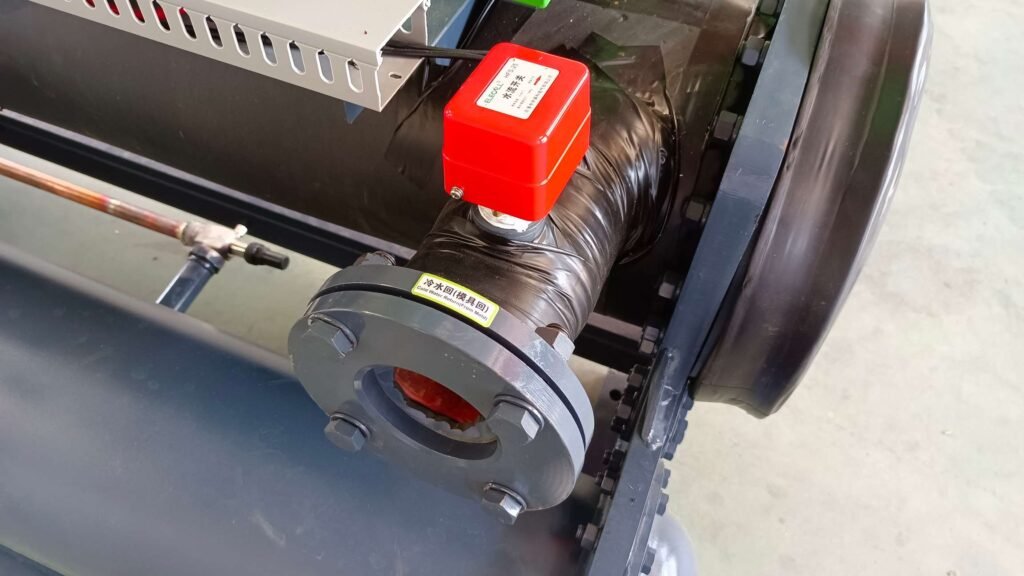

The equipment adopts horizontal shell and tube condenser and shell and tube evaporator, which has compact structure, high heat exchange efficiency and easy maintenance. Its unique circular motion design ensures that the equipment has no “surge” phenomenon when operating at low load, with noise as low as 75 dB(A) and minimal vibration. In addition, the equipment uses high-quality materials and precision manufacturing processes to ensure long-term stable operation, with an average trouble-free operation time of more than 20,000 hours.

3. Intelligent control and easy operation

The control system adopts imported PLC program controller, equipped with a 10-inch large-screen touch screen, with a simple and intuitive interface and supports remote monitoring and operation. Users can view the equipment operation status in real time through mobile phones or computers and adjust parameters.

4. Multiple protections, safe and worry-free

The equipment has built-in multiple safety protection systems, including compressor overload protection, water pump overload protection, poor heat dissipation protection, refrigerant shortage protection, freezing prevention protection, high voltage protection, low voltage protection, power reverse phase and phase loss protection, etc. These protection mechanisms effectively prevent the equipment from being damaged under abnormal working conditions and ensure the safe operation of the equipment in various environments.

技術パラメーター

| モデル | KF-114KW | KF-157KW | KF-205KW | KF-227KW | KF-276KW | KF-298KW | KF-350KW | KF-369KW | KF-411KW | KF-443KW | KF-482KW | KF-585KW | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Capacity | kW/h | 114 | 157 | 205 | 227 | 276 | 298 | 350 | 369 | 411 | 443 | 482 | 585 | |

Kcal/h | 98040 | 135020 | 176300 | 195220 | 237360 | 256280 | 301000 | 317340 | 353460 | 380980 | 414520 | 503100 | ||

| Input Power | KW | 23.5 | 31.1 | 39 | 42.9 | 51.4 | 56.1 | 63.7 | 67.7 | 73.9 | 80.2 | 88.3 | 105.8 | |

| 電圧 | 3PH-380V-50Hz(Or200V/220V/415V50Hz/60Hz) | |||||||||||||

| Refrigerant | 名称 | R22(Or R134a/R407c) | ||||||||||||

| 制御方法 | Outside The Balanced Thermal Expansion Valve | |||||||||||||

| Compressor | Types | Semi-Closed Screw Compressor | ||||||||||||

| Start Mode | Y-△ | |||||||||||||

| Energy Control | 0-25-50-75-100 | |||||||||||||

| Evaporator | Types | ShellAnd Tube | ||||||||||||

| Chilled Water(m³/h) | 20 | 27 | 35 | 39 | 48 | 51 | 60 | 64 | 71 | 76 | 83 | 101 | ||

| Water Pipe(DN) | 65 | 65 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | ||

| Condenser | Types | Shell And Tube | ||||||||||||

| Cooling Water(m³/h) | 22 | 30 | 39 | 42 | 52 | 55 | 66 | 70 | 77 | 83 | 91 | 110 | ||

| Water Pipe(DN) | 65 | 65 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | ||

| Overall dimensions | L(mm) | 2580 | 2580 | 2635 | 3095 | 3144 | 3149 | 3150 | 3198 | 3198 | 3198 | 3275 | 3660 | |

| W(mm) | 900 | 900 | 900 | 900 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | ||

| H(mm) | 1328 | 1328 | 1426 | 1506 | 1521 | 1753 | 1731 | 1776 | 1915 | 1915 | 2110 | 2110 | ||

| Unit weight | KG | 710 | 750 | 1155 | 1335 | 1585 | 1700 | 1860 | 2005 | 2465 | 2615 | 3165 | 3410 | |

| Unit Conversion | 1KW=860KCAL/HR 1RT=3024KCAL/HR 1BTU/HR=0.252KCAL/HR | |||||||||||||

| モデル | KF-611KW | KF-676KW | KF-732KW | KF-760KW | KF-886KW | KF-953KW | KF- 1037KW | KF- 1171KW | KF- 1320KW | KF- 1507KW | KF- 1690KW | KF- 1961KW | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Capacity | kW/h | 611 | 676 | 732 | 760 | 886 | 953 | 1037 | 1171 | 1320 | 1507 | 1690 | 1961 | |

Kcal/h | 525460 | 581360 | 629520 | 653600 | 761960 | 819580 | 891820 | 1007060 | 1135200 | 1296020 | 1453400 | 1686460 | ||

| Input Power | KW | 108.2 | 121.8 | 130.3 | 136.3 | 139 | 167.6 | 183 | 206.8 | 232 | 258.1 | 288.3 | 332.8 | |

| 電圧 | 3PH-380V-50Hz(Or200V/220V/415V50Hz/60Hz) | |||||||||||||

| Refrigerant | 名称 | R22(Or R134a/R407c) | ||||||||||||

| 制御方法 | Outside The Balanced Thermal Expansion Valve | |||||||||||||

| Compressor | Types | Semi-Closed Screw Compressor | ||||||||||||

| Start Mode | Y-△ | |||||||||||||

| Energy Control | 0-25-50-75-100 | |||||||||||||

| Evaporator | Types | Shell And Tube | ||||||||||||

| Chilled Water(m³/h) | 105 | 117 | 126 | 131 | 153 | 164 | 179 | 202 | 228 | 260 | 291 | 338 | ||

| Water Pipe(DN) | 125 | 150 | 150 | 150 | custom made | custom made | custom made | custom made | custom made | custom made | custom made | custom made | ||

| Condenser | Types | Shell And Tube | ||||||||||||

| Cooling Water(m³/h) | 114 | 127 | 137 | 143 | 166 | 178 | 194 | 219 | 247 | 281 | 315 | 365 | ||

| Water Pipe(DN) | 125 | 150 | 150 | 150 | custom made | custom made | custom made | custom made | custom made | custom made | custom made | custom made | ||

| Overall | L(mm) | 3995 | 4330 | 4610 | 4610 | - | - | - | - | - | - | - | - | |

| W(mm) | 1100 | 1300 | 1300 | 1300 | - | - | - | - | - | - | - | - | ||

| dimensions | H(mm) | 2110 | 2880 | 2350 | 2350 | - | - | - | - | - | - | - | - | |

| Unit weight | KG | 4151 | 4780 | 5333 | 5950 | - | - | - | - | - | - | - | - | |

| Unit Conversion | 1KW=860KCAL/HR 1RT=3024KCAL/HR 1BTU/HR=0.252KCAL/HR | |||||||||||||

Benefits of Water-cooled screw chiller

1. Reduce operating costs

The efficient and energy-saving design of the water-cooled screw chiller can significantly reduce power consumption.

2. Improve production efficiency

The equipment can provide stable cooling effect for production equipment and ensure temperature control during the production process.

3. Extend equipment life

The equipment uses high-quality materials and advanced manufacturing processes to ensure long-term stable operation. The multiple protection system effectively prevents equipment from being damaged under abnormal working conditions and extends the service life of the equipment.

4. Wide applicability

Water-cooled screw chillers are not only suitable for industrial production, but also for commercial air-conditioning systems, providing comfortable indoor environments for shopping malls, hotels, office buildings, hospitals, data centers and other places.

詳細

The whole machine uses high-quality parts

The models all adopt Siemens electronic components, liquid crystal display microcomputer controller, export standard, Chinese and English option, simple operation; It can display the cold water inlet, cold water outlet and set temperature at the same time; Can accurately control the water temperature.

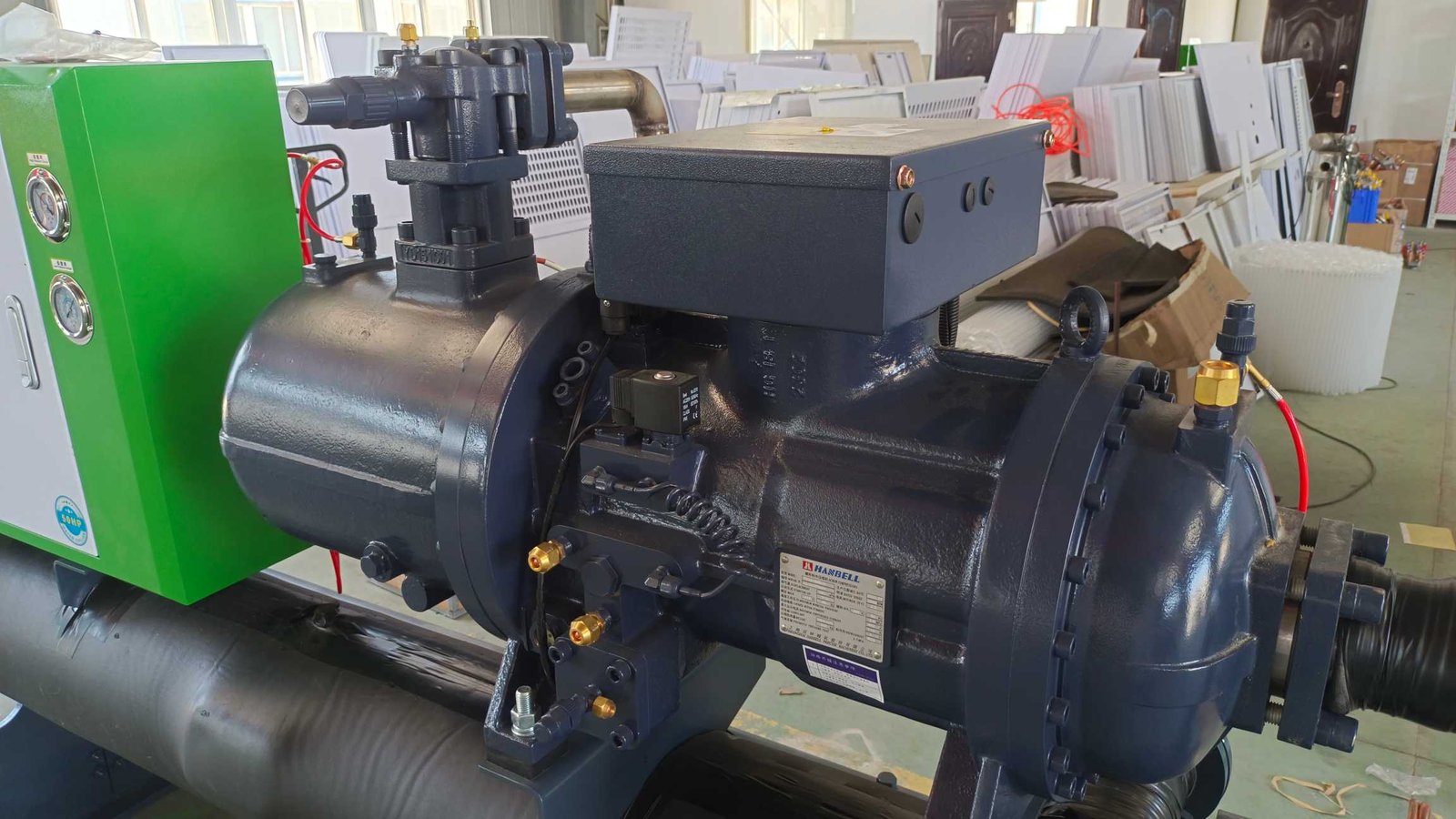

High-quality screw compressor

Optional the best screw compressor brands in the world High reliability, few parts, no wearing parts, so reliable operation, long life, generally up to 30 years of service life; Good power balance, no unbalanced inertial force, the machine can work smoothly and at a high speed, and realize no foundation operation; It has strong adaptability, has the characteristics of forced gas transmission, is suitable for a variety of working conditions, and is easy to finalize mass production.

Multiple external protections to ensure the high-performance operation of the chiller

The use of a new type of aviation hose, high pressure resistance, high temperature resistance, vibration resistance, and better prevent the problem of refrigerant leakage; Emerson filter, filter impurities, with 304 stainless steel pipeline to further ensure the purity of the refrigerant and protect the compressor.

Double cooling system, better cooling effect

High efficiency shell and tube evaporator with high-efficiency shell and tube condenser

アプリケーション・シナリオ

1. Industrial production

Plastic processing industry: Provide cooling for injection molding machines, extruders and other equipment to ensure product molding quality.

Chemical industry: Provide cooling for reactors, distillation towers and other equipment to ensure production safety.

Pharmaceutical industry: Provide cooling for fermentation tanks and sterilization equipment to ensure the quality of drugs.

Food and beverage industry: Provide cooling for production lines to extend the shelf life of products.

2. Commercial air conditioning

Shopping malls and hotels: provide cooling for central air conditioning systems to create a comfortable indoor environment.

Hospitals and data centers: provide cooling for precision equipment to ensure stable operation of equipment.

よくあるご質問

1. What is the maintenance cycle of water-cooled screw chillers?

It is recommended to perform comprehensive maintenance every six months, including cleaning the condenser, checking the amount of refrigerant, checking the electrical system, etc.

2. Is the equipment noisy when running?

The equipment adopts a low-noise design, and the noise level during operation is ≤75 dB(A), which is suitable for use in noise-sensitive environments.

3. Does the equipment support remote monitoring?

Yes, the equipment supports remote monitoring function. Users can monitor the operating status of the equipment in real time through mobile phones or computers and perform remote operations.

4. What is the energy efficiency ratio (EER) of the equipment?

The energy efficiency ratio (EER) of the equipment is high. The specific value varies depending on the model, generally above 3.5.

5. Does the equipment support customization?

Yes, we can provide customized solutions according to customers’ specific needs, including cooling capacity, dimensions, control methods, etc.