KAIFENG Machinery:

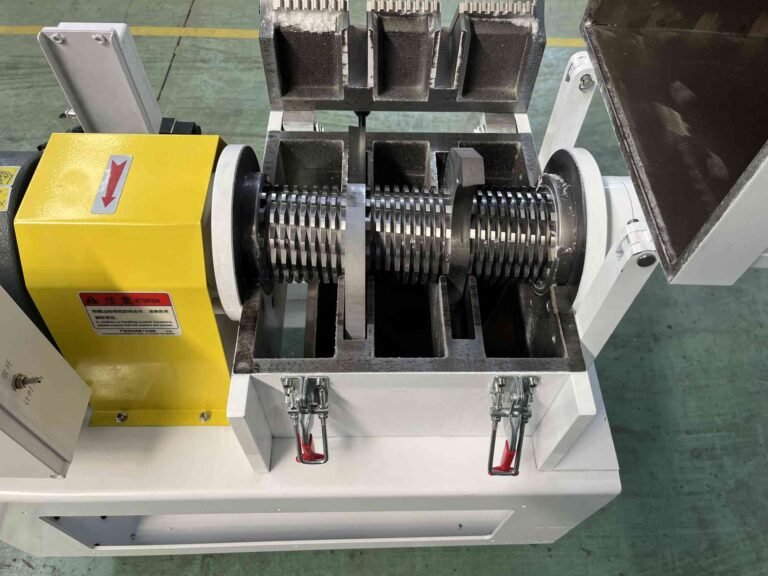

Your reliable shredder and crushing machine manufacturer

Our crushing and recycling equipment is built for operations that need consistent performance and clean output shift after shift. From processing plastics and rubber to handling leftover materials for reuse, each machine is designed to keep your workflow smooth and cost‑effective. Whether you’re starting a new recycling line or upgrading an existing plant, our equipment is ready to meet the demand.

We inspect every stage of production, using durable components and proven engineering to help minimize maintenance and downtime. Each model can be configured for your specific materials and throughput needs. If you want a solution that works reliably without unnecessary complexity, we offer an efficient way to start, expand, or optimize your recycling process.