Introduction to Air-cooled screw chiller

Air-cooled screw chiller is an energy-efficient refrigeration equipment widely used in industrial production and commercial air conditioning. It adopts advanced screw compressor technology and combines intelligent control system to provide users with stable and efficient refrigeration solutions. Whether it is chemical, pharmaceutical, food and beverage industry, or injection molding, die casting, rubber molding and other industrial fields, Air-cooled screw chiller can meet the diverse cooling needs and ensure the stable operation of production equipment and product quality.

Features of Air-cooled screw chiller

1. High efficiency and energy saving

Adopting high-efficiency screw compressor and equipped with graded energy regulation system, it can significantly reduce the operating cost. Through intelligent energy regulation, the equipment can automatically adjust the operating state according to the actual load to avoid energy waste. For example, after using our equipment, a chemical company reduced its annual energy consumption by 15%, saving a lot of electricity bills.

Built-in deep supercooling technology to improve refrigeration efficiency and reduce energy consumption. It can still maintain efficient operation in high temperature environment to ensure stable refrigeration effect.

2. Intelligent control

Equipped with PLC control system, it supports startup control, energy regulation, fault diagnosis and other functions, and is easy to operate. Users can easily set parameters through the touch screen and monitor the operating status of the equipment in real time.

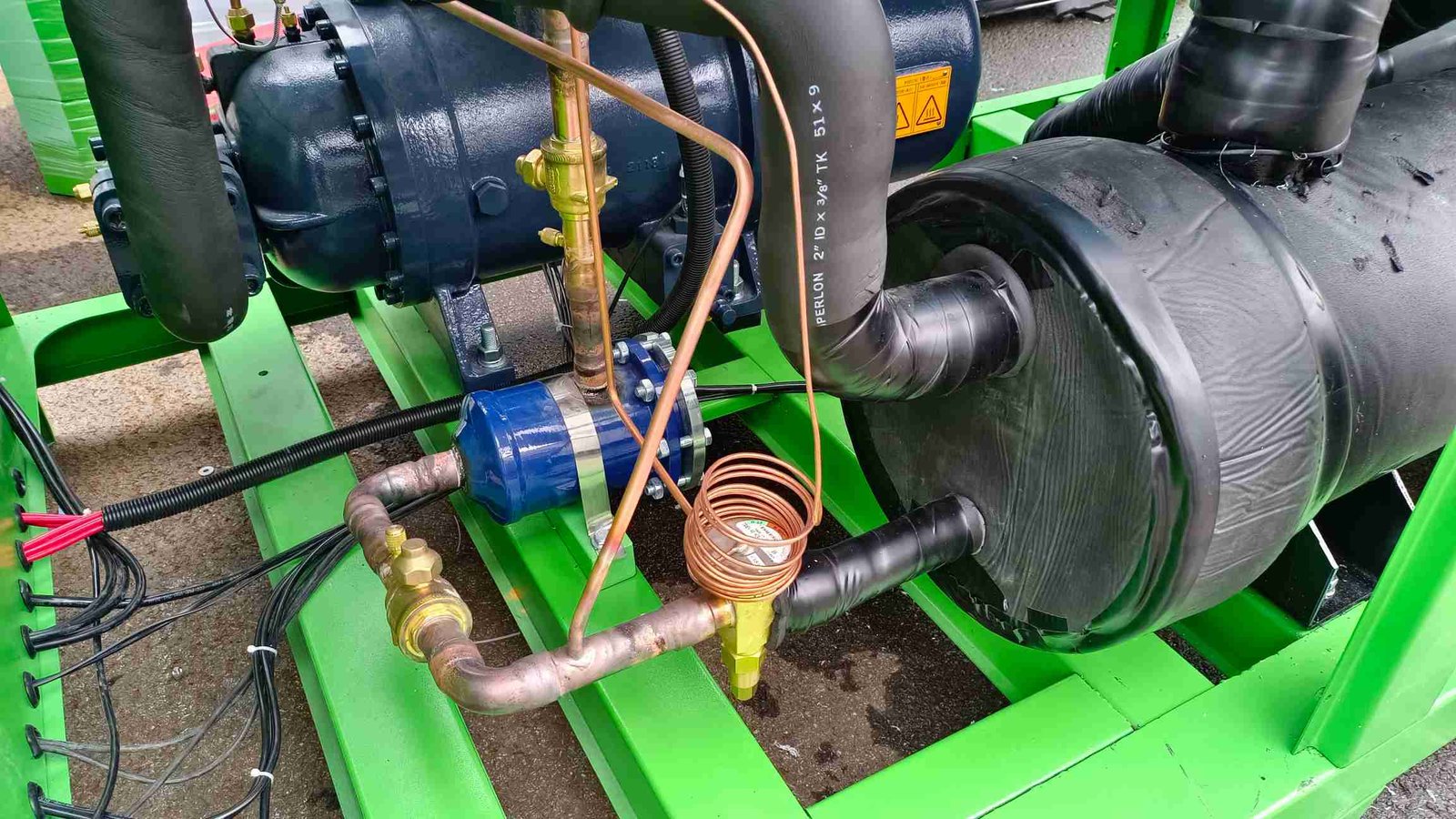

3. High-quality materials

The evaporator adopts a high-efficiency shell and tube heat exchanger with built-in threaded copper tubes, which has excellent cooling effect. The copper tubes are specially treated for strong corrosion resistance and long service life.

The condenser adopts a hydrophilic fin design, which has high heat exchange efficiency and faster heat dissipation. The surface of the fins is specially coated to prevent dust accumulation and ensure long-term efficient operation.

4. Multiple protections

Built-in compressor protection, system pressure protection and other multiple safety mechanisms ensure long-term stable operation of the equipment. When the equipment is abnormal, the system will automatically alarm and take protective measures to avoid equipment damage.

The equipment is also equipped with overload protection, phase loss protection and other functions, which further improves the safety of operation.

Technical Parameter

| Model | KF-99KW | KF-137KW | KF-181KW | KF-193KW | KF-241KW | KF-259KW | KF-306KW | KF-323KW | KF-360KW | KF-387KW | KF-421KW | KF-511KW | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Capacity | kW/h | 99 | 137 | 181 | 193 | 241 | 259 | 306 | 323 | 360 | 387 | 421 | 511 | |

| Kcal/h | 85140 | 117820 | 155660 | 165980 | 207260 | 222740 | 263160 | 27780 | 309600 | 332820 | 362060 | 439460 | ||

| Input Power | KW | 28.3 | 37.4 | 47 | 51.7 | 62 | 67.7 | 76.8 | 81.7 | 89 | 96.6 | 106.5 | 127.5 | |

| Voltage | 3PH-380V-50Hz(Or200V/220V/415V50Hz/60Hz) | |||||||||||||

| Refrigerant | Name | R22(Or R134a/R407c) | ||||||||||||

| Control Method | Outside The Balanced Thermal Expansion Valve | |||||||||||||

| Compressor | Types | Semi-Closed Screw Compressor | ||||||||||||

| Start Mode | Y-△ | |||||||||||||

| Energy Control | 0-25-50-75-100 | |||||||||||||

| Evaporator | Types | Shell And Tube | ||||||||||||

| Chilled Water(m³/h) | 17 | 24 | 31 | 33 | 42 | 45 | 53 | 56 | 62 | 67 | 73 | 88 | ||

| Water Pipe(DN) | 65 | 65 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | ||

| Condenser | Types | Shell And Tube | ||||||||||||

| Cooling Water(m³/h) | 19 | 26 | 35 | 37 | 46 | 50 | 59 | 62 | 69 | 75 | 81 | 99 | ||

| Water Pipe(DN) | 65 | 65 | 80 | 80 | 100 | 100 | 100 | 100 | 125 | 125 | 125 | 125 | ||

| Overall dimensions | L(mm) | - | - | - | - | - | - | - | - | - | - | - | - | |

| W(mm) | - | - | - | - | - | - | - | - | - | - | - | - | ||

| H(mm) | - | - | - | - | - | - | - | - | - | - | - | - | ||

| Unit weight | KG | - | - | - | - | - | - | - | - | - | - | - | - | |

| Unit Conversion | 1KW=860KCAL/HR 1RT=3024KCAL/HR 1BTU/HR=0.252KCAL/HR | |||||||||||||

| Model | KF-535KW | KF-591KW | KF-640KW | KF-665KW | KF-774KW | KF-833KW | KF-907KW | KF- 1023KW | KF- 1154KW | KF- 1317KW | KF- 1478KW | KF- 1714KW | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cooling Capacity | kW/h | 535 | 591 | 640 | 665 | 774 | 833 | 907 | 1023 | 1154 | 1317 | 1478 | 1714 | |

| Kcal/h | 460100 | 508260 | 550400 | 571900 | 665640 | 716380 | 780020 | 879780 | 992440 | 1132620 | 1271080 | 1474040 | ||

| Input Power | KW | 130.4 | 146.8 | 157 | 164.3 | 187.3 | 202 | 220.6 | 249.2 | 279.7 | 311.1 | 347.5 | 401.2 | |

| Voltage | 3PH-380V-50Hz(Or200V/220V/415V50Hz/60Hz) | |||||||||||||

| Refrigerant | Name | R22(Or R134a/R407c) | ||||||||||||

| Control Method | Outside The Balanced Thermal Expansion Valve | |||||||||||||

| Compressor | Types | Semi-Closed Screw Compressor | ||||||||||||

| Start Mode | Y-△ | |||||||||||||

| Energy Control | 0-25-50-75-100 | |||||||||||||

| Evaporator | Types | Shell And Tube | ||||||||||||

| Chilled Water(m³/h) | 92 | 102 | 110 | 115 | 133 | 144 | 156 | 176 | 199 | 227 | 255 | 296 | ||

| Water Pipe(DN) | 125 | 150 | 150 | 150 | Custom-made | Custom-made | Custom-made | Custom-made | Custom-made | Custom-made | Custom-made | Custom-made | ||

| Condenser | Types | Shell And Tube | ||||||||||||

| Cooling Water(m³/h) | 103 | 114 | 123 | 128 | 149 | 161 | 175 | 197 | 222 | 254 | 285 | 330 | ||

| Water Pipe(DN) | 125 | 150 | 150 | 150 | Custom-made | Custom-made | Custom-made | Custom-made | Custom-made | Custom-made | Custom-made | Custom-made | ||

| Overall dimensions | L(mm) | - | - | - | - | - | - | - | - | - | - | - | - | |

| W(mm) | - | - | - | - | - | - | - | - | - | - | - | - | ||

| H(mm) | - | - | - | - | - | - | - | - | - | - | - | |||

| Unit weight | KG | - | - | - | - | - | - | - | - | - | - | - | ||

| Unit Conversion | 1KW=860KCAL/HR 1RT=3024KCAL/HR 1BTU/HR=0.252KCAL/HR | |||||||||||||

Benefits of Air-cooled screw chiller

1. Reduce operating costs

Through efficient energy regulation and natural cooling technology, power consumption is significantly reduced and operating costs are reduced. The equipment automatically enters energy-saving mode when running at low load, further saving energy.

No need to install a cooling water tower, saving installation and maintenance costs. The air-cooling design reduces water consumption and is particularly suitable for areas with scarce water resources.

2. Improve production efficiency

Precise temperature control (temperature difference can reach ±0.3℃) ensures temperature stability during production and improves product quality. The equipment adopts PID control algorithm, which can quickly respond to temperature changes and maintain constant temperature.

Quick start function, resume operation within 45 seconds after power failure, reducing production interruption time. The equipment also has a power failure memory function, which automatically returns to the previous operating state after power is restored.

3. Environmentally friendly and sustainable

The use of environmentally friendly refrigerants (such as R134a) has no destructive effect on the atmospheric ozone layer and meets green environmental protection requirements. The equipment also supports a variety of environmentally friendly refrigerants to meet environmental regulations in different regions.

Reduce carbon dioxide emissions through efficient operation and promote sustainable development. The equipment strictly follows environmental protection standards during the design and manufacturing process to reduce the impact on the environment.

4. Strong adaptability

Wide temperature operating range (-35℃~45℃), suitable for a variety of complex environments. Whether it is a high-temperature workshop or a low-temperature warehouse, the equipment can operate stably.

Modular design can be flexibly expanded according to demand to meet cooling needs of different scales. Users can add or reduce modules according to actual needs to achieve optimal resource allocation.

Detials

Application Scenarios

1. Industrial production

Chemical industry: Provide cooling for equipment such as reactors and distillation towers to ensure stable production processes. The equipment can withstand corrosive gases in chemical environments to ensure long-term stable operation.

Food and beverage industry: Used for production line cooling to ensure food quality and hygiene safety. The equipment uses food-grade materials, meets hygiene standards, and ensures food safety.

Plastic processing industry: Provide cooling for equipment such as injection molding machines and extruders to improve production efficiency. The equipment can quickly reduce mold temperature and shorten production cycles.

2. Commercial air conditioning

Shopping centers: Provide efficient cooling for central air conditioning systems to create a comfortable shopping environment. The equipment has low operating noise and will not affect customers’ shopping experience.

Data centers: Use natural cooling technology to reduce server operating temperature and ensure data security. The equipment can run 24 hours a day and meet the strict requirements of the data center.

3. Other fields

Pharmaceutical industry: used for cooling pharmaceutical production equipment to ensure the quality of pharmaceuticals. The equipment can provide a constant temperature environment to meet the high-precision requirements of pharmaceutical production.

Electronics industry: Provide a constant temperature environment for precision instruments to improve product qualification rate. The equipment can respond quickly to temperature changes to ensure the stability of electronic components.

FAQ

1. Does the Air-cooled screw chiller require a cooling water tower?

No. The Air-cooled screw chiller adopts an air-cooled design, and no additional cooling water tower is required, saving installation space and cost. The air-cooled design also reduces water consumption, which is particularly suitable for areas with scarce water resources.

2. How is the operating noise of the equipment?

The equipment adopts a low-noise design. By optimizing the fan and compressor structure, the operating noise is significantly reduced, and it is suitable for noise-sensitive environments. The noise of the equipment is less than 65 decibels during operation and will not interfere with the surrounding environment.

3. Is the maintenance of the equipment complicated?

The equipment is equipped with intelligent diagnostic function, which can monitor the operating status in real time and provide fault warning, which is easy to maintain. Users only need to clean the filter and check the operating status of the equipment regularly to ensure long-term stable operation of the equipment.

4. Does it support customized requirements?

Yes. We can provide customized solutions with different capacities, configurations and functions according to the specific needs of customers. Whether it is the operating requirements in special environments or specific cooling needs, we can tailor it for you.