Introduction to Medium-speed Side Crusher

Medium-speed Side Crusher is an efficient crushing equipment designed for plastic and rubber recycling. The equipment is suitable for being placed beside the injection molding machine and used in combination with recyclers, dryers, etc. to form a set of rapid recycling system. The feeding hopper is designed with an upward opening, which is convenient for cooperating with manipulators and conveyor belts to further reduce intermediate links, avoid manpower loss and material waste, and can better improve work efficiency, reduce material pollution, and save labor. Its unique design and efficient performance make it popular in the plastic and rubber recycling industry. Whether it is a small factory or a large production line, the medium-speed side crusher can provide a stable and efficient crushing solution to help companies achieve efficient use of resources and optimized cost control.

Features of Medium-speed Side Crusher

1. Intelligent functions

Automated operation: The medium-speed side crusher can work seamlessly with the manipulator and conveyor belt to achieve automated operation. By reducing manual intervention, it not only improves work efficiency, but also reduces the risk of human operating errors.

Intelligent control system: The equipment is equipped with advanced electrical components, and the operation interface is simple and intuitive, and users can easily set and adjust parameters. The intelligent control system can also monitor the operating status of the equipment in real time to ensure that the equipment is always in the best working condition.

2. Ingenious design

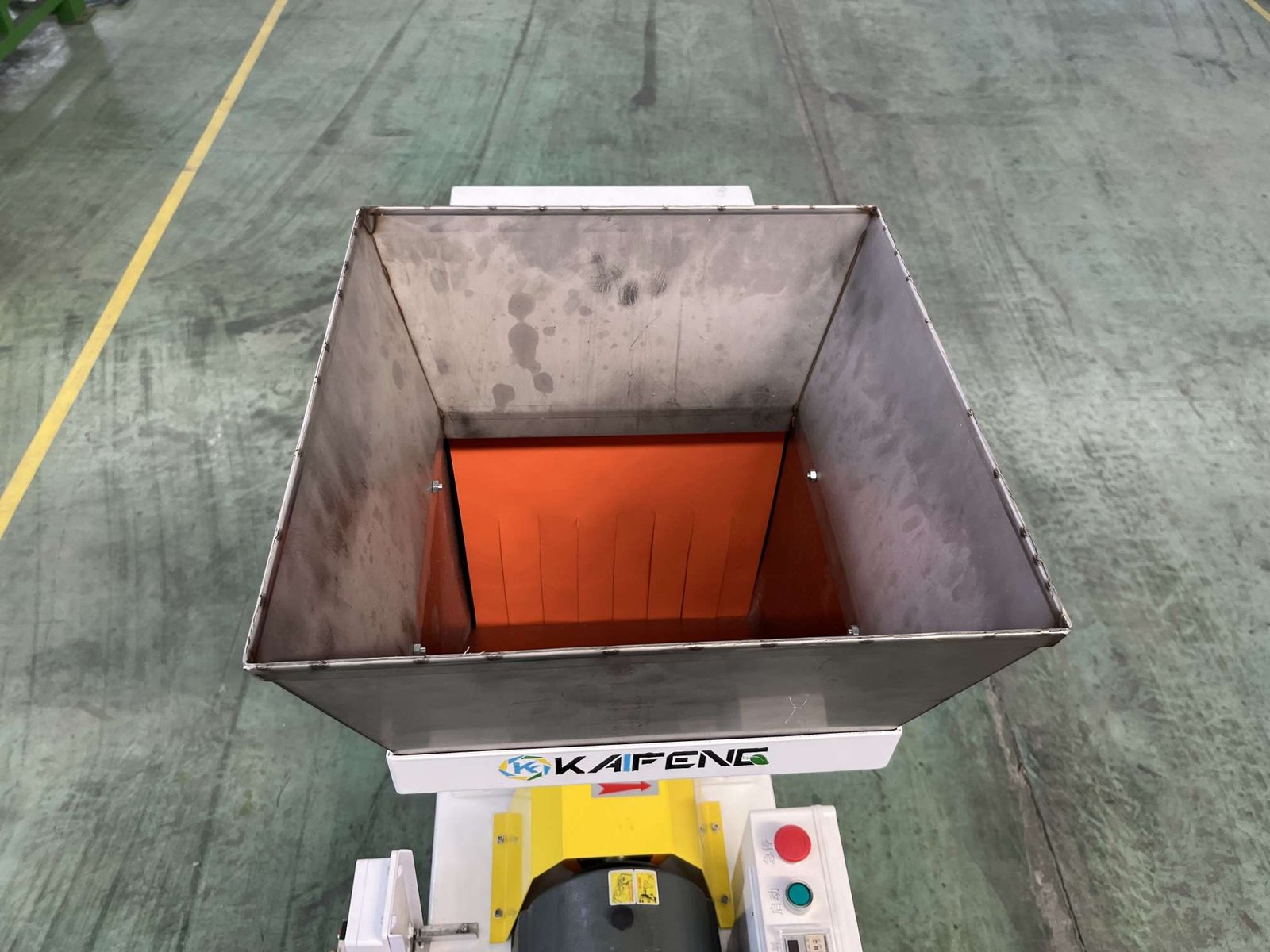

Feed hopper: The feed hopper is designed with an inclined angle to effectively prevent the material from popping out during the crushing process. The inner wall is made of stainless steel, which is not only corrosion-resistant, but also prevents material contamination, ensuring the purity of the crushed material.

Receiver tray: Made of stainless steel, the structure is sturdy and durable, and easy to clean and maintain. The design of the receiving tray also takes into account the smoothness of the material flow, ensuring that the crushed material can be discharged quickly to avoid blockage.

Technical Parameter

| Model | Caliber (MM) | Screen Mesh | Crushing Capacity (Kg/h) | Rotating Speed | Power (kW) | Dimensions (mm) | Weight (Kg) |

| PJB290-10 | 282×290 | 6 mm | 30-150 | 140 | 2.2 | 900×460×1250 | 192 |

| PJB310-13 | 375×310 | 6 mm | 70-150 | 140 | 3.75 | 1180×560×1400 | 240 |

| PJB429-15 | 282×429 | 6 mm | 100-200 | 140 | 3.75 | 1180×560×1460 | 265 |

Benefits of Medium-speed Side Crusher

1. Reduce power consumption

High efficiency and energy saving: The medium-speed side crusher adopts a full copper wire motor with low energy consumption and high operating efficiency. While ensuring efficient crushing, the equipment significantly reduces power consumption, helping enterprises save energy costs.

Intelligent energy-saving mode: The equipment is equipped with an intelligent energy-saving mode, which automatically adjusts power output under low load conditions to further reduce energy consumption.

2. Reduce costs

Reduce manpower: Automated operation reduces labor costs, and the ingenious design of the feed hopper reduces material waste, further reducing production costs.

Long service life: High-quality materials and precision manufacturing processes ensure the durability of the equipment, reduce the frequency of equipment replacement and maintenance, and thus reduce long-term operating costs.

3. Avoid risks

Safe and reliable: The equipment uses world-renowned Siemens electrical components, with stable performance, safety and reliability. The intelligent control system can also monitor the operating status of the equipment in real time, detect and warn potential problems in a timely manner, and avoid the risk of production interruption caused by equipment failure.

Environmentally friendly design: The feed port is equipped with a curtain to effectively reduce dust pollution in the workshop, meet environmental protection requirements, and help enterprises avoid environmental risks.

Detials

High-quality knife set, long service life

Equipped with a blade cutter set, the blade material is CR12MOV, moderate hardness, wear resistance, uniform crushing particles, low noise;

The cutter shaft is made of 45# quenched and tempered steel, which has a lesser degree of rotating wear.

Ingenious feeding hopper design

Ingenious design of the tilt angle of the feeding hopper, the material will not be ejected from the feeding hopper when crushed;

The stainless steel inner wall is used to prevent the paint from being hit by the material and prevent the material from being contaminated;

The feeding port is equipped with a curtain to further reduce dust pollution in the workshop.

Electrical components

Using world-renowned brand Siemens electrical components, stable performance, safe and reliable.

Receiving tray

Constructed of stainless steel, durable.

All copper wire motor

Using well-known trademark motors, prolonged service life and durable.

Application Scenarios

Around the injection molding machine: The medium-speed side crusher is suitable for being placed around the injection molding machine and used in conjunction with the recycling machine and dryer to form a rapid recycling system. Through automated operation, the intermediate links are reduced and production efficiency is improved.

Plastic and rubber recycling: It is widely used in the plastic and rubber recycling industry and is suitable for the crushing and recycling of various plastic and rubber products. Whether it is hard plastic or soft rubber, the equipment can handle it efficiently.

Small factories and large production lines: The equipment occupies a small area and has low energy consumption. It is suitable for production environments of various sizes and meets the needs of different customers.

FAQ

What is the service life of the medium-speed side crusher?

The medium-speed side crusher adopts high-quality materials and advanced manufacturing technology. The blades and knife shafts are highly wear-resistant and have a long service life. Under normal use and maintenance, the equipment can operate stably for many years.

Is the equipment noisy during operation?

The medium-speed side crusher is reasonably designed, the blade cuts evenly, and the noise is low, which is suitable for use in a quiet environment. The equipment is also equipped with a noise reduction design to further reduce the noise during operation.

Can the screen aperture be customized?

High-quality and stable screens can be customized according to customer needs to meet different crushing needs. The customized screen aperture range is wide and suitable for various material crushing scenarios.

How to maintain the equipment?

The equipment has a simple structure and is easy to disassemble and clean. It is recommended to regularly check the wear of the blades and knife shafts and replace the worn parts in time. The equipment is also equipped with an intelligent monitoring system that can remind users to perform maintenance in real time.