Introduction to slow speed side crusher

The Slow-Speed Side Crusher is a CE/PED-certified low-speed side-mounted plastic crusher machine, engineered for seamless integration with injection molding machines, dryers, and recycling systems. Designed to handle thick, tough materials like sprue residues (ABS, PC, Nylon) and production scrap, it delivers dust-free operation (<5mg/m³ emissions), ultra-quiet performance (68dB), and extended blade longevity (HRC60-62 hardened steel). With an annual raw material cost savings of up to $28,000, this plastic crusher enables real-time scrap recycling, reducing waste rates to ≤5%.

Features of slow speed side crusher

1. Low-Speed Dust-Free Shredding Technology

Staggered Cutting Process: 15-30 RPM motor + helical serrated blades enable progressive shearing (vs. high-speed impact), reducing dust emissions by 90% (ISO 14001 compliant).

Heavy-Duty Material Processing: Crushes engineering plastics up to 50mm thick, including PA+GF (glass-filled nylon) and POM (acetal), with blades lasting 8,000+ hours (cryogenically treated + TiN coating).

2. intelligent Safety Control

Dual Anti-Jamming Protection: Torque sensors trigger 0.5s auto-reverse upon overload, while optional metal detectors halt operation for impurities ≥Φ2mm.

3. Modular Energy-Saving Design

Rapid Deployment: Side-mounted feed inlet (450×300mm) aligns with standard press discharge heights; installation completed in 30 minutes.

40% Lower Energy Consumption: Achieves 0.8kW·h/kg (vs. 1.3kW·h/kg for conventional crushers), saving $5,200/year (8hrs/day operation).

Technical Parameter

| Caliber (MM) | Number of Blades | Crushing Capacity (Kg/h) | Rotating Speed (rpm) | Power (kW) | Dimensions (mm) | Weight (Kg) | ||

| Fixed Blades | Rotary Blades | S Blades | ||||||

| 250×240 | 3 | 4 | 2 | 10-15 | 23 | 1.1 | 900×450×1180 | 160 |

| 315×315 | 3 | 8 | 2 | 20-25 | 23 | 1.5 | 1100×520×1220 | 200 |

| 410×315 | 4 | 8 | 3 | 25-30 | 23 | 2.2 | 1200×520×1250 | 260 |

| 420×350 | 4 | 8 | 3 | 40-50 | 23 | 3 | 1200×560×1300 | 326 |

| 480×380 | 4 | 8 | 3 | 100-120 | 23 | 4 | 850×610×1550 | 750 |

Benefits of slow speed side crusher

1. Cost Reduction & ROI Maximization

Zero Scrap Inventory: Crushed granules are directly reused, boosting material utilization by 95%.

Minimal Maintenance: Quick-change blade cartridge reduces downtime to 15 minutes; annual upkeep costs <$500.

2. Risk-Free Operation

Contamination Prevention: Fully enclosed structure + optional negative-pressure dust ports ensure ≥98% pellet purity.

Global Compliance: CE/PED certification support worldwide voltage (380V/415V/460V).

3. Industry-Specific Adaptability

Harsh Environment Ready: Optional heated air knives (prevents PET sticking) and anti-corrosion coating (high-humidity workshops).

Medical-Grade Recycling: FDA-compliant configurations for PET/PVC medical scrap processing.

Detials

High-quality knife set, long service life

The slow-speed crusher adopts SKD-11 material pineapple knife;No screen design, dust-free and uniform crushing material;

The cutter shaft is made of 45# quenched and tempered steel, which has a lesser degree of rotating wear.

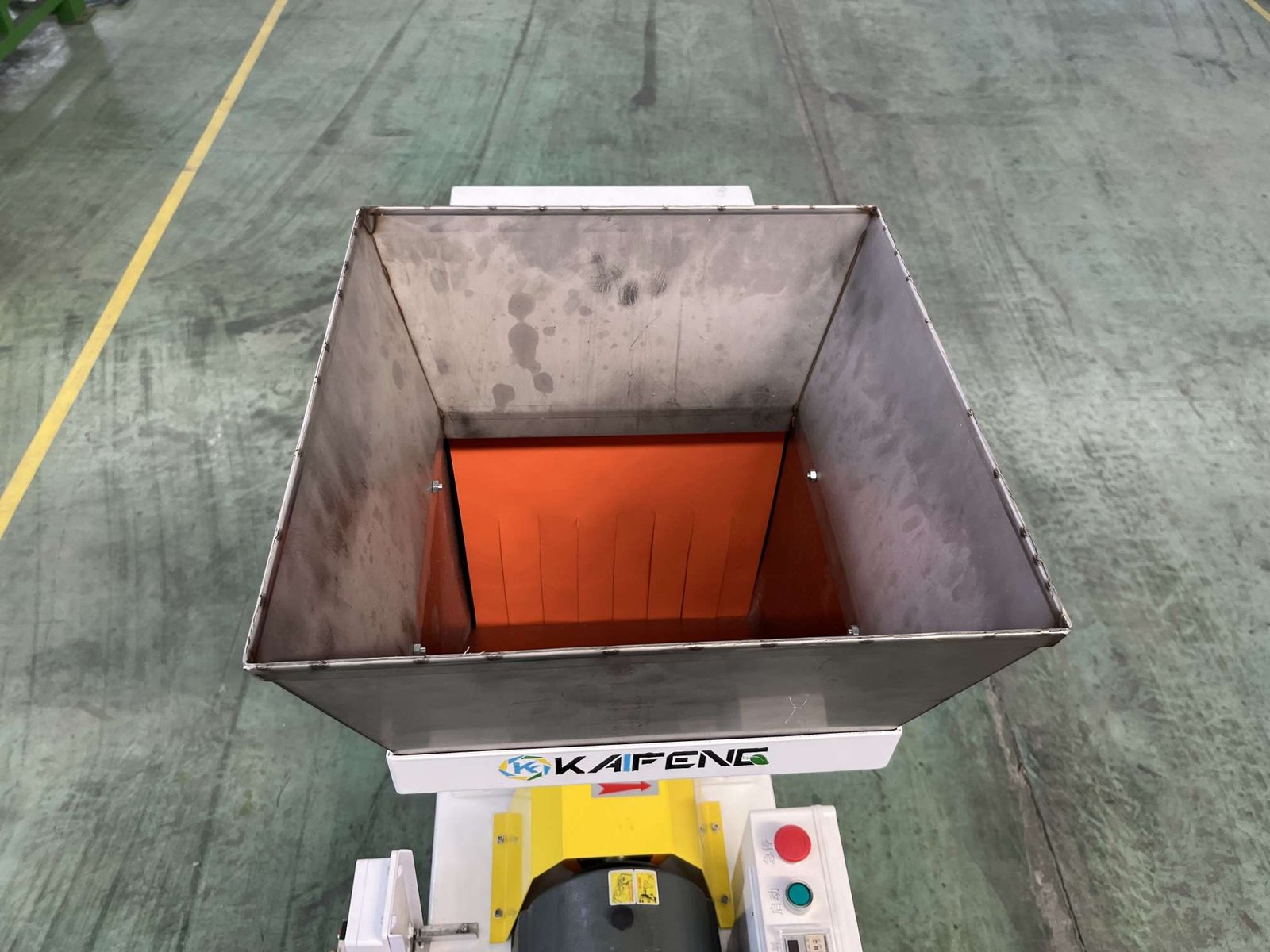

Ingenious feeding hopper design

Ingenious design of the tilt angle of the feeding hopper, the material will not be ejected from the feeding hopper when crushed;

The stainless steel inner wall is used to prevent the paint from being hit by the material and prevent the material from being contaminated;

The feeding port is provided with a curtain to further reduce dust pollution in the workshop.

Electrical components

Using world-renowned brand Siemens electrical components, stable performance, safe and reliable.

Receiving tray

Constructed of stainless steel, durable.

All copper wire motor

Using well-known trademark motors, prolonged service life and durable.

Application Scenarios

1. In-Line Molding Recycling

Automated Closed Loop: Robotic arm transfers sprue materials to crusher, with vacuum conveying to dryers (max. 30% regrind ratio).

Defective Part Recycling: Uniform Φ8mm granules prevent mold clogging during re-injection (e.g., short shots, flash).

2. Industry-Tailored Solutions

Industry | Typical Applications | Materials | Custom Configurations |

Automotive | Bumper gates, dashboard scrap | PP/ABS/PA+GF | HRC62 blades, metal detection |

Electronics | Phone housings, connectors | PC/ABS | Dust-free ports, anti-static devices |

Medical | IV bottle caps, PVC tubing | PET/PVC | FDA-approved Φ4mm screens, SS316 body |

3. Challenging Environments

High Humidity: Anti-condensation circuits + stainless bearings (90% RH tolerance).

Metal Contamination: Optional separator detects Φ1.5mm Fe/Al/Cu particles.

FAQ

Is an external dust collection system required?

Standard models meet <5mg/m³ dust emissions. For medical-grade cleanliness, add negative-pressure modules (+$1,200).

Can oily/labeled plastics be processed?

Only dry, clean scrap is recommended. Contact us for pre-washing system designs.

How does screen size affect regrind ratios?

Smaller screens improve flowability but reduce throughput:

Φ12mm: Max. output, ideal for thick parts (<15% regrind).

Φ8mm (default): Balanced performance (10-25% regrind).

Φ4mm: Precision shredding for thin walls (≤30% regrind).

What is your standard delivery time?

For standard units with 380V/50Hz/3Phase, it’s about 3~7 working days. Other voltages may take up to 15~20 working days. For a customized unit, it may take up to 20~30 working days.

What is the standard warranty period?

One year on all the mechanical parts and three months of all consumable parts from the date of B/L.